For businesses looking to outsource some or all of their electronics manufacturing, we understand how important it is to choose a supplier that is the right fit for your business and offers the most potential for a long and profitable partnership.

Here are four vital areas to explore when considering any potential manufacturing partner.

Do they have extensive experience in contract electronic manufacturing (CEM)?

It is sometimes hard to decide when it comes to picking a good supplier, however, one key thing to consider is the level of experience that they have of producing high quality, consistent electronics-based parts or products. Are they able to keep customers for the long-term and what do those customers say about them?Also, how do they manage the three key factors - price, delivery and quality? After all, it is no good choosing on price alone, as factors such as trust, service and flexibility need to be taken into account. What is the supplier’s delivery promise and have they kept it in the past?

Have they invested in the latest technologies and equipment?

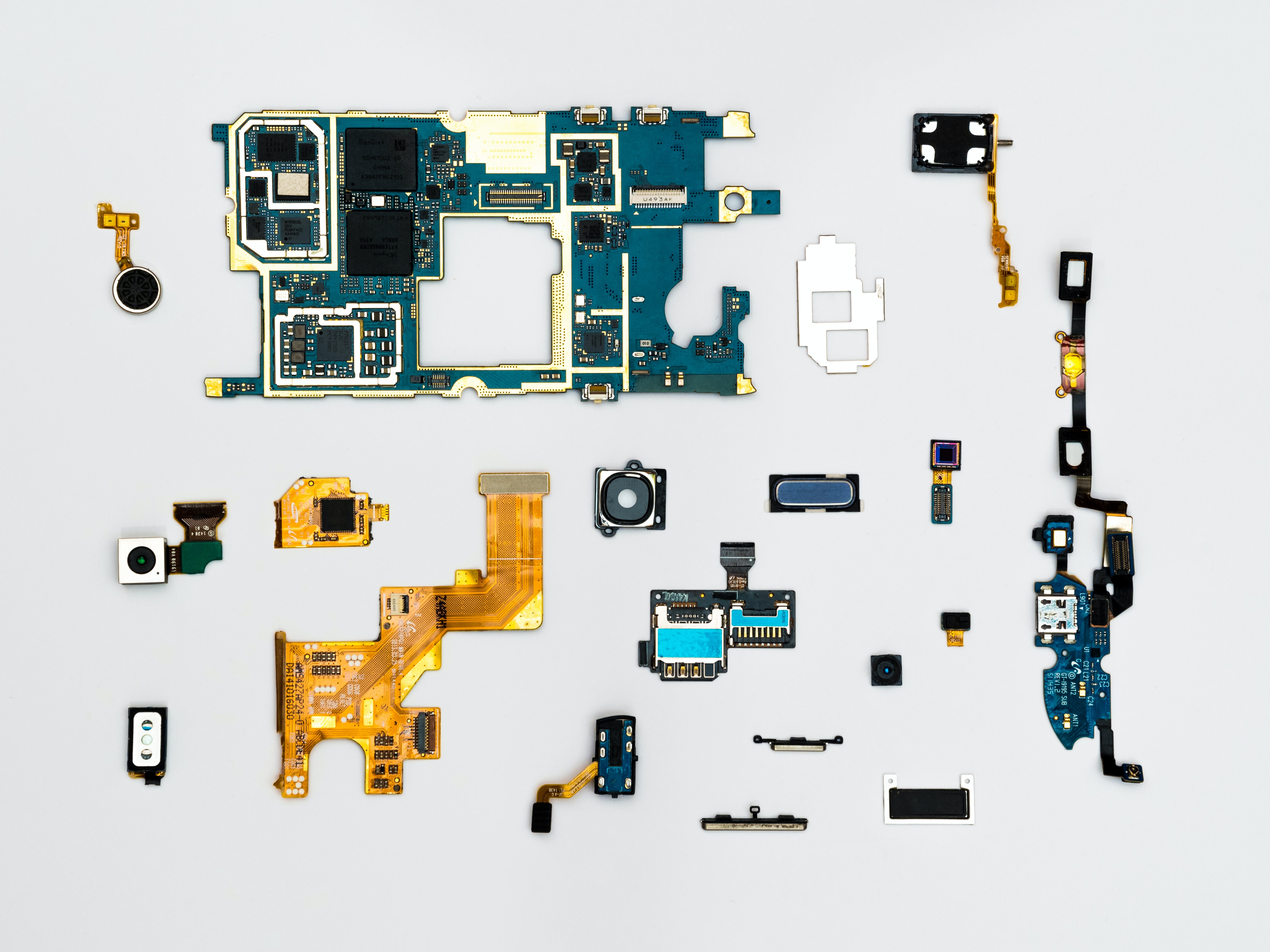

Any CEM that is interested in keeping their customers happy and delivering a cost-effective, high-quality service will have invested in ongoing and advanced manufacturing and testing technologies. Ask them what clients they have worked with and what equipment has been produced as a result. This will help determine their production capabilities and showcase their in-house expertise that is controlling the process and what equipment is being used.

Other questions to consider asking are:

- What was the latest piece of equipment purchased?

- What are their capabilities for their 3D printing equipment?

Do they have a new product introduction process in place?

A new product introduction (NPI) process helps OEMs and manufacturers of electronic products drive down production costs, improve quality and reduce time to market. However, it requires an experienced NPI team at the contract electronics manufacturers to put it in place. With an experienced team and an NPI in place, lead-times are kept as short as possible, product over-engineering is avoided and component choice is optimised. Click here to find out more about CB Technology’s NPI and prototyping capabilities.

How comprehensive is their product testing strategy?

You can’t guarantee the quality of a product without putting it to the test. When done correctly, testing ensures a product is in full working order and saves time and money in the longer-term. If the CEM’s testing strategy is inadequate, there is a risk that the end products will be of inferior quality and this could trigger expensive recalls or refund requests.

As no single testing system for PCB assembly meets the requirements of every manufacturing run, you will need a CEM who can show that they have a strategy in place for determining the most efficient and cost-effective method of validating and testing their PCBs to required specifications.

Ultimately, choosing a CEM supplier relies on an assessment of both quantitative and qualitative measures.